Control of Starting Materials in Good Manufacturing Practice

- Published on: Dec 16, 2020

The independent quality control over starting materials is a critical step of manufacture is a basic GMP requirement. Since quality commences with the quality of materials. it’s important to verify that starting materials meet specifications before use. This is not after use. This is even more important for a new vendor, since there is no history of supply.

The laboratory has a change of government approved tests that verify the identity, potency, purity and quality of the raw material. While the Certificate is helpful, it does not substitute for actual sampling and testing.

GMP specifically only authorizes the Quality Unit to decide on the release or rejection of materials, Purchasing, IT, and Warehousing do not have this authority.

The final product is only as good as the starting materials used. To ensure the purity, identity, effectiveness and solely of finished products:

- Materials must be purchased only from approved suppliers to written specifications.

- All incoming materials must be inspected and/or tested to verify their suitability for use.

- Label all materials clearly to indicate their inspection and lest status.

- Materials must be stored safely to protect from deterioration and damage.

- Records must be maintained for all issued material in order to ensure traceability.

- Checking that the identification is exactly the same on the container as it is on the paperwork

- Examining each container and verifying that containers are sealed, undamaged and clean

- Reporting raw materials when the contents are exposed

- Raising a non-conformance notice before accepting the material if any problems arise

- Supplier audit

- Number of acceptable consecutive deliveries

- Verification of test results

- Supplier audit

- Number of acceptable consecutive deliveries

- Verification of test results

- Supplier questionnaire

- On-time delivery and other commercial issues

- Authenticity of Certificate of Analysis verified (lot number, signatory, company, results are in specification, etc.)

- Remove the supplier’s status labels

- Apply the company’s identification and status labels

- Record the receipt of goods on company documentation

- Quarantine materials immediately after they have been accepted

- Check and process goods as soon as possible to help prevent material mix-ups and damage

- Follow exactly the written procedures for sampling to ensure that the sample represents the container it was taken from.

- Take samples in a separate area to prevent contamination.

- Test according to the methods detailed or referenced in the specifications

- The sampler wears glove to protect both the person and the chemical from being cross-contaminated.

- The sampler is gowned to protect the chemical from contamination.

- The sampling spoon is clean and inert to the chemical.

- The chemical container is lined with plastic to protect the chemical from the outer cardboard.

- The sample jar is amber to protect the chemical from light.

- The sample jar is labelled on the body, not on the lid.

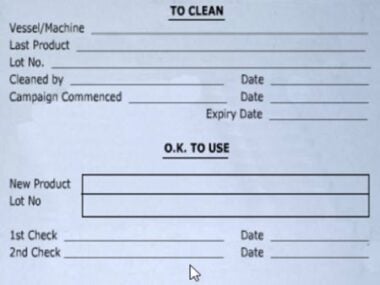

- Always use clean equipment, and inspect cleanliness prior to use.

- Always sample in a clean environment with air protection to prevent cross-contamination.

- Always sample wearing personal protection, including hat, gloves, coats, and where required, a mask.

- Always refer to specific MSDSs and SOPs for sampling precautions.

- Follow the sampling instructions exactly, which should specify sample size, sample number, and location of sampling.

- Only operators trained in sampling technique should take samples.

- Reseal containers after sampling, and label the containers that have been sampled from.

- Ensure that the sample itself is properly labelled on the body of the container, not on the lid.

- The nature of the material

- The history of the supplier

- Whether there is a valid certificate of analysis

- The company’s QA program

- Physical labels on the container

- Electronic fields on a database

- A combination of physical and electronic

- Temperature must be monitored in storage areas, and the results must be regularly checked.

- There must be pest control program to ensure that raw materials are not contaminated by rats, mice, birds, cockroaches, etc.

- Any discrepancies in inventory must be investigated

- Items must be stored off the floor and away from walls

- Stores operate on a “First In, First Out” (FIFO) basis to ensure that the oldest material is used first.

- Only authorised personnel should be permitted into the storage areas. Visitors should be accompanied.

- GMP rules require separate areas for materials with different statuses, and the status of the material must match its associated location at all times.

- Regular stock takes are necessary to verify that the physical stock matches the paperwork.

- Starting materials and components must be stored in designated locations.

- Separate quarantine and reject areas.

- The storage environment should be temperature-controlled.

- Store goods off the floor and away from walls.

- Employ a system that identifies material about to expire so that it can be retested if necessary.

- Periodically inspect stockrooms for past-expiry expired stock, cleanliness, housekeeping, and pest control.

- Seal over all opened containers to protect from the environment.

- Materials should only be issued from the store by authorised persons following a written procedure.

- Records of the quantities receipted into stock and the quantities issued to manufacturing must be maintained.

- Inventory records should be maintained in such a way that any discrepancy between the quantity received and the quantity issued can be clearly seen.

- Discrepancies are to be reported and investigated.

- Always follow procedures. Report any deviations or abnormalities

- Process batches in accordance with master documents.

- Operators must be trained in SOPs.

- Online testing provides assurance that the product is within specification.

- Manufacturing records must be completed accurately and completely, and should include all information relating to processing and testing.

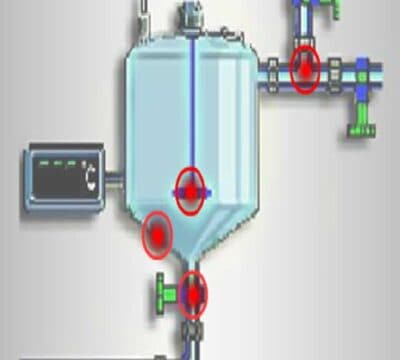

- Bulk containers and other major items of equipment should be labelled with the name, strength and batch number of product being processed.

- In-process items should be clearly labelled.

- Store materials in designated areas

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.

Related Posts

You may like to read these related posts.

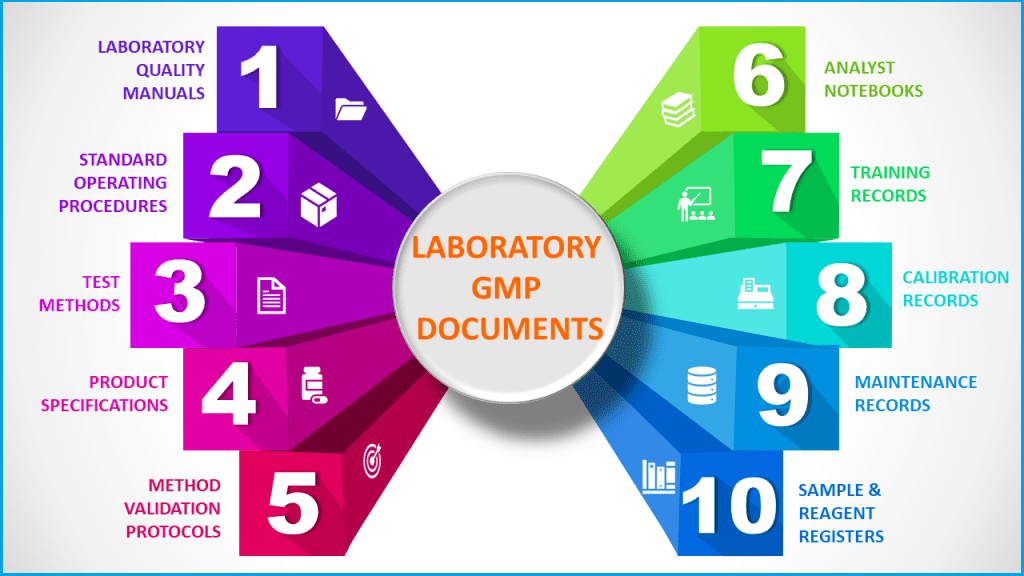

Expected Compliance Standards for Quality Control Laboratories

Cleaning Validation for Active Pharmaceutical Ingredients

How to perform metal detection in pharmaceuticals processes

How do you store “R&D” labeled material in a GMP environment?

Informative and helpfull