Disposition of Production Materials and Finished Products at a GMP Site

- Kazi

- Last modified: August 1, 2024

This article defines the requirements for the Disposition of materials used and products produced, at GMP sites involving:

- Drug Products including Validation and demonstration Batches.

- Active Pharmaceutical Ingredients (API) including validation and demonstration batches

- Raw Materials (RM);

- API Starting Materials;

- Intermediates;

- In-Process Materials;

- Medical Devices;

- Packaging Materials; and

- Other Materials.

- Applicable Material Control Documents (MCD);

- Compendial Specifications, where applicable; and

- Review of associated documentation [e.g., Certificate of Analysis (COA), batch Records, Device History Record (DHR) and Certificate ofCompliance].

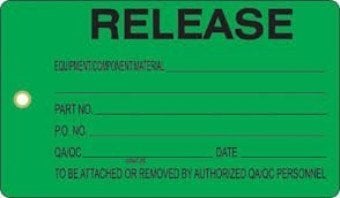

- Material status indication has to be addressed.

- An inspection performed by the site; and

- Periodic (at least annual) confirmation of supplier test results.

- Deviation investigation reports [e.g., Laboratory Investigation Report (LIR) and Quality Deviation Report (DR) have been completed and approved

- Any applicable change control;

- Correct Expiration Date or Re-evaluation Interval has been assigned to the finished product; and

- Results from examination of the final finished pack, when required.

- Each batch of medicinal products manufactured within the European Community have been produced and tested/checked in accordance with the local regulatory directives and the marketing authorisation.

- For medicinal products manufactured outside the European Community, a Qualified Person must ensure that each imported batch has undergone, in the importing country required testing.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.