How to Develop Quality Control Method and Specifications for a Laboratory

- Kazi

- Last modified: April 2, 2024

Pharmacopoeial monographs provide general conditions for developing quality control method. Pharmacopoeial methods are considered robust as they have been validated in multiple laboratories, but each laboratory will use unique instrumentation, different analysts and probably prepare samples differently.

This means that pharmacopoeial methods should be verified as suitable for each laboratory in which they are used: this is a form of validation. Part of the verification and transfer to the laboratory involves preparing a specific quality control method that is validated and used for initial analyst training. It is expected that companies publish specific in-house methods.

Quality Control Method

Laboratory quality control methods have a well-defined lifecycle, from origin to publication, through to update and retirement. GMP and QC rules determine these pathways.

A typical quality control layout is shown as follows

1.0 Policy and Definitions

2.0 Equipment and Materials

2.1 Equipment

2.2 Materials

3.0 Procedure

4.0 General Requirements

5.0 Test Method -Contents

5.1 Principal of the method

5.2 Materials list

5.2.1 Materials and reagents

5.2.2 Instrument description (including instrument settings)

5.3 Test Procedures

5.3.1 Preparation of standard solution

5.3.2 Preparation of sample and # of replicates required

5.3.3 Preparation of positive and negative controls

5.3.4 Test procedure and instrument settings

5.3.4.1 Instrument setting and preparation

5.3.4.2 Start up

5.3.4.3 Shut down

5.3.4.4 General operation

5.3.4.5 Data entry standards

5.3.4.6 Computer controls

5.3.5 Step-by-step procedure description

5.4 Reading the test endpoint

6.0 Calculations -include an example where warranted

7.0 Test acceptance criteria

7.1 Validity of the test -list system suitability criteria

7.2 Repeat testing

7.2.1 Invalid Test

7.2.2 Samples which fail specification

8.0 References and attachments

210 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

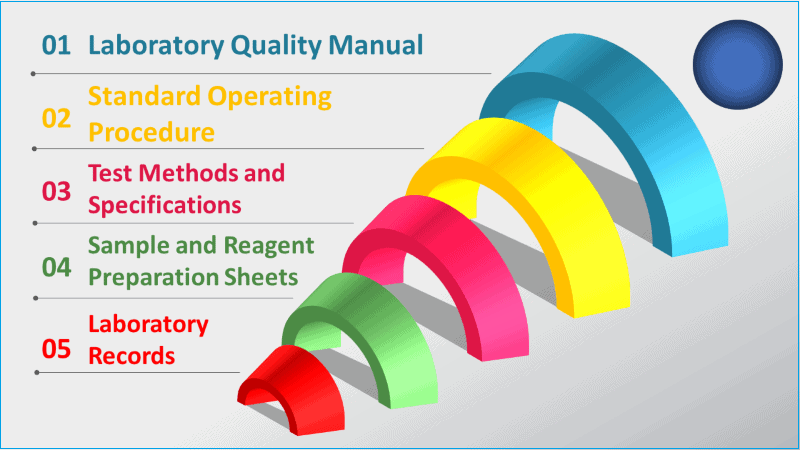

Laboratory Documentation Hierarchy

Development of quality control method

Source of quality control method

Quality control method generally originates from one of three sources. These include official pharmacopoeias, new methods from a development laboratory, and/or adopted from literature.

Method development

During development, methods are tested for suitability according to the product they are being used for, and the analytical validation performance parameters.

Published method

Once a quality control method has been suitably developed, it is published in a format that should be unambiguous and easy to follow far an analyst. The published method should also reference any instrumentation and corresponding settings.

Quality control method validation

Once a method is published, it must be validated according to ICH Q2(R1), or equivalent criteria. This method validation package should confirm the suitability of the method. The validation report is generally submitted to a regulatory agency as proof that the method is lit for use and validated.

Transfer to QC laboratory

When a test method is suitably validated, it is transferred to the QC laboratory for commercial use. At this point, QC analysts become responsible for the test method.

Verify suitability

As part of the technology transfer, validated quality control methods must be verified as to their suitability in the QC laboratory. This generally involves partial validation to confirm that the transferred method remains in a validated state and is still fit for use in QC laboratory, its instruments and analysts.

Use of quality control method in testing

The test method is used for the routine testing of target products, and if properly validated and transferred, should be reliable and robust.

Integrity and accuracy of a test method

The accuracy, precision and selectivity of test methods are critical to the reliability of test results.

To ensure the integrity and accuracy of a test method, the following pre-requisites are recommended:

– accurate and unambiguous interpretation of the written method

– proper training of the analysts on the method

– properly calibrated and maintained equipment

– in-built performance checks per run

– clear instruction on how to prepare samples

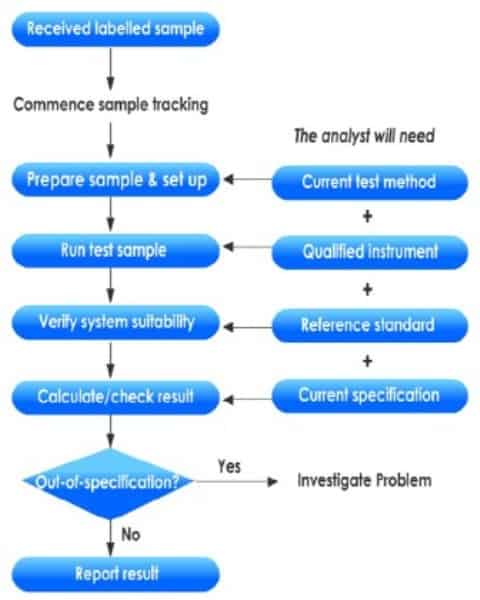

Typical sample processing in the laboratory

The QC lab fallows a series of documented steps to test a sample. Each of these steps is supported by a current and validated test method, a qualified instrument, a calibrated reference standard and an approved specification.

1. Received Labelled Sample: The laboratory maintains a Sample Receiving Register. This register logs the batch and sample number, number of samples provided and the time and date the sample first entered the laboratory. This is the commencement of sample tracking.

2. Prepare sample and set up: Many quality control methods require sample preparation before the test is run. The test method should describe exactly how the sample is prepared. This may involve simple dilution or more complex extraction and manipulation. Always refer to the current test method before setting up the sample.

3. Run test sample: Once the sample is prepared, it is included in the test run. Care must be taken to ensure that the sample is not degraded, e.g. by spillage, exposure to atmosphere or temperature degradation on the bench. Always refer to the current test method for instructions and how to protect the sample during testing. Concurrent with testing the sample, analysts should ensure that the instrument or a logbook records the sample number and it is traced exactly to the test result.

4. Verify system suitability: For instrumental runs such as HPLC/GC, the test method usually includes a verification that the entire instrumental system is performing satisfactorily on the day of the run. This is called “system suitability testing” (SST). Non-instrumental methods may also include control or equivalent verification systems. The test methods should describe how the integrity of particular test runs is verified.

5. Calculate / check result: Once the sample has been run, either the instrument or the analyst will perform a calculation to arrive of a result. It is essential to double check all calculations before finalizing sample results.

6. Out of specifications (OOS)? All QC laboratories have written procedures for handling and investigating only result that appears to be OOS. The analyst should ensure that as soon as an OOS event occurs supervision is notified, the sample is retained and a documented investigation is commenced.

7. Current test method: Before commencing any assay, the analyst should refer to the current version of the test method. The test method should be available at the worksite.

8. Qualified instrument: Samples must be processed through qualified and calibrated instruments. The analyst should be aware of the status of the instrument before conducting the test. In particular, the analyst should pay attention to the instrument calibration status. If an instrument is out of calibration, do not proceed with the test. All laboratory instruments, upon introduction to the laboratory should undergo formal qualification.

9. Reference standard: Many tests require comparison of the sample to an official reference standard. The same core should be taken in preparing the reference standard as is taken when preparing the sample for test. The analyst should ensure that only the current approved reference standard should be used. The reference standard number must be recorded in the test record.

10. Current specification: In all QC testing laboratories, there will be a set al published and approved specifications for each starting material and finished product. When calculating and checking results, the analyst should refer to the current specification to decide the status of the sample. These specifications are often registered with the regulatory agency and cannot be changed.

Importance of specifications

Specification documents define official quality control method and limits packaging materials, starting materials, components, bulk products and finished products. These may also apply to critical steps of manufacture.

Quality Control specifications should conform to statutory standards (e.g. pharmacopoeias) and any specifications accepted by regulatory bodies for approval of the product or in connection with its registration.

Failure to meet specification should result in out-of-specification (OOS) notice and investigation. If the OOS is confirmed, the sample will be rejected and a nonconformance report issued.

a. Starting Materials:

In the pharmaceutical industry, the requirements for starting materials must be well-defined and documented to ensure that you get the material specified or ordered, and that there are no mixups.

Starting materials are defined by a standard name, the supplier’s/manufacturer’s code, and a unique item code.

Specifications for starting materials should include:

- inspections and/or tests required

- reference to test methods and acceptance criteria

- material storage conditions

- a retest or expiry date

- reference to pharmacopoeial method (if available)

- approved supplier and manufacturer (if available)

- sampling instruction or reference

- any precautions

2. Intermediate products

In the pharmaceutical industry, specifications for intermediate and bulk products should be available if these are received or dispatched, or if data obtained from tests on intermediate or bulk products are used for the evaluation of the finished product or further processing.

The specifications should be similar to specifications for starting materials or for finished products, as appropriate.

3. Packaging materials

In the pharmaceutical industry, the requirements for pre-printed packaging materials must be well-defined and documented to ensure that you get the items you specified or ordered, and that there are no mixup.

Packaging materials are defined by a standard name, and a unique item code.

Specifications for packaging materials should include:

- a detailed description of the item

- inspections and/or tests required

- acceptance criteria

- an approved label copy

- approved supplier and manufacturer (if available)

- sampling instruction or reference

- storage conditions

- any precautions

4. Finished products

Specifications for products typically include:

- an exact statement of the active material

- the product code (if any)

- the dosage form and/or strength

- physical appearance and identity

- all tests and their limits

- details of, or reference to, the test methods

- sampling instructions

- the shelf life and storage conditions

- designated name

- package details

- formula (or reference to a formula)

- any precautions

Pharmacopoeias

Pharmacopoeias are published standards often recognized by regulatory agencies as official standards. Many countries make compliance to pharmacopoeias a condition of release to market for each batch. Any official or legal methods will prevail in any dispute situation.

The main sections included in pharmacopoeias are:

- general notices for dose forms (e.g. tablets, liquids, sterile products)

- monographs for raw materials and products, covering the official tests, test methods, and information on how to conduct particular tests

- guidance on conducting general tests

- preparation of standard reagents

Products and raw materials that are compliant to pharmacopoeias must continue to comply during the entire lifetime of the goods.

Where a pharmacopoeia is applicable to a starting material, this is a minimum specification, and the Quality Control specifications used should at least conform to it.

Reference standards

A primary reference standard is a substance that has been shown by an extensive set of analytic tests to be authentic material that should be of high purity. Primary standards are recognized by the pharmacopoeias and regulatory agencies as the official industry standards for particular tests.

Primary standards can be:

- obtained from an officially recognized source

- prepared by independent synthesis

- obtained from existing production material of high purity ifthere is no other external primary standard available

- prepared by further purification of existing production material

Secondary reference standards are also substances of established quality and purity, usually prepared in-house. These standards can only be used if they are standardized against primary standards using definitive methods that are published in pharmacopoeias and national and international standards.

Wherever economically possible, primary standards should be used.

Primary Standards

Chemical and biological primary standards or reference materials or obtainable via:

- BP, EP, USP

- WHO for biologicals

- ANSI

- USA Bureau for Biologicals

- College of American Pathologists (CAP) for clinical standards

- USA National Bureau of Standards (NBS)

Reference standards and any secondary standards prepared from them should be dated and stored, handled and used so as not prejudice quality. A register should be used to record the source, identity and any other available information concerning the preparation and characterization of these substances, as well as the date put Into service and date taken out of service.

Reagents and Standard Solutions

Reagents made up in the laboratory should be prepared following standard procedures. As applicable, labelling should indicate the concentration, standardization factor, shelf life and storage conditions. The label should be dated and signed or initialed by the person preparing the reagent.

Where relevant, a date for re-standardization should be recorded. In certain cases, it may be necessary to carry out tests to confirm that the reagent Is suitable for the purpose for which it is to be used. A record of these tests should be maintained. Where appropriate, purchased reagent solutions should be dated upon receipt.

The accuracy and precision of tests results and test methods is dependent on the reliability, authenticity, and control over reference standards, reagents, and stock solutions.

Similarly, the retrospective testing of materials and product is dependent on the protection and storage of retention samples.

Summary

Quality control methods and test specifications are important components of quality control documentation pyramid. Where appropriate quality control methods should be referenced through relevant standard operating procedures and product specifications. While there are some reputed sources of quality control methods worldwide, it is strongly recommended to validate those in house for robustness and fit for purpose by the laboratory before use. Quality control methods and specifications that are developed internally must pass a rigorous validation process and should be approved by the local regulatory bodies before being allowed to use for testing.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.