How to develop supplier relationship management strategies in GMP

- Kazi

- Last modified: March 15, 2025

Table of Contents

What is supplier relationship management?

Supplier relationship management (SRM) can be defined as a systematic approach to build relationship with suppliers to achieve long term value and benefits for the business.

All of our suppliers are important, but not all have the equal capacity to influence our business operations. For instance, in a pharmaceutical manufacturing business, a supplier of Active Pharmaceutical Ingredients influences the business more critically than the stationary or catering supplies.

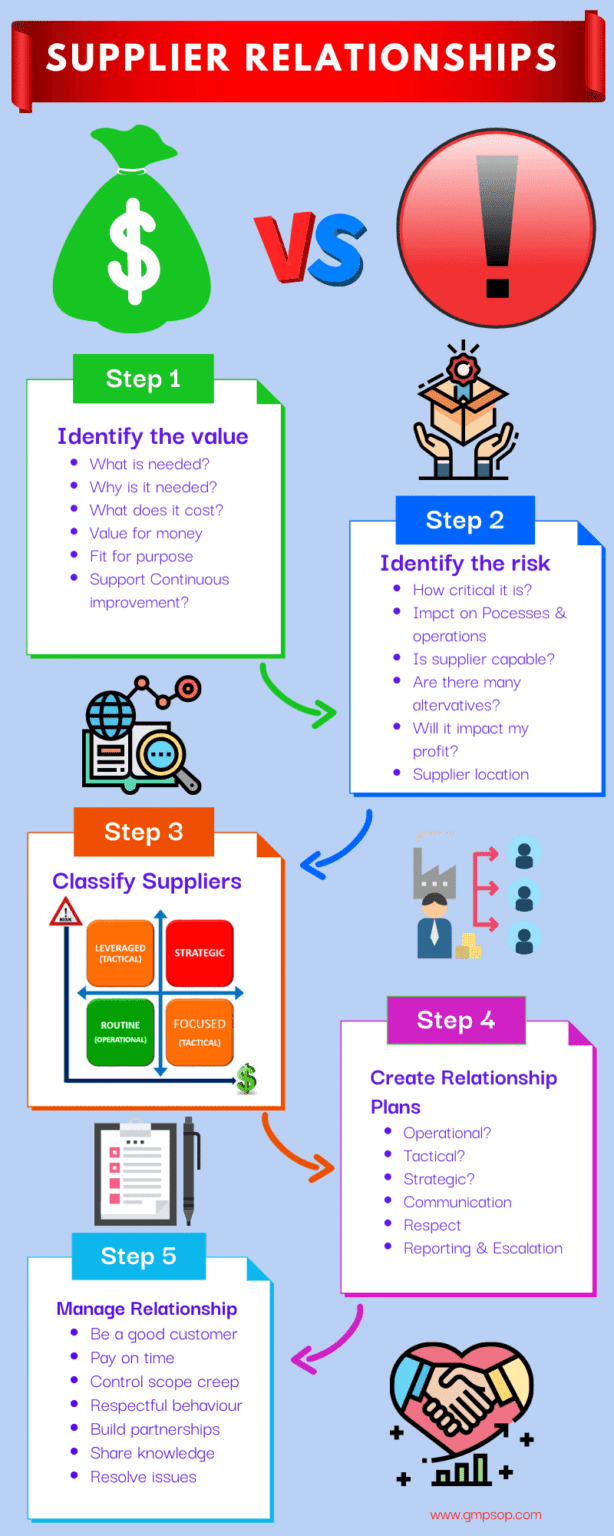

Determination of supplier’s contribution over the business operations through the assessment of value, risks and supply security will eventually lead to classification of key suppliers among others. As we can classify key suppliers the next step is develop relationship plans appropriate to the level of supplier.

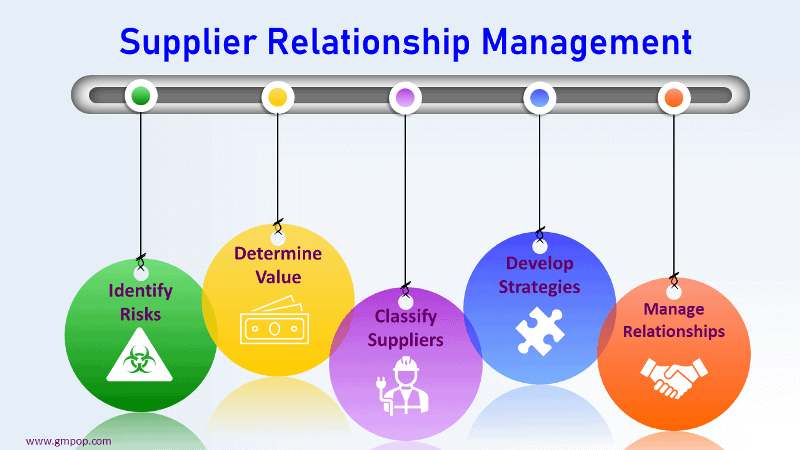

In a nutshell, the supplier relationship management involves:

- Identification of values in supply

- Classification of suppliers through value and risks

- Development of supplier engagement strategies

- Management of appropriate level of relationships

Value of supplier relationship management to customer

- The ultimate goal of SRM is to improve business processes efficiency between customer and supplier

- SRM strategies facilitate collaborative supplier relationship

- Develop long term mutually beneficial partnership with the key suppliers

- Promotes supply security for the business in the longer term

- Improves knowledge sharing between partners where required

- Fill technological gap where exist

- Long term income security for the supplier

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

Supplier relationship matrix

There are four segments in the supplier relationship matrix. Each of the suppliers belongs to one of these segments within the matrix. The relationship plans should match the corresponding segment of supplier.

Based on the values and risks of the supplied items, suppliers are categorised as operational, tactical or Strategic levels. There are other factors that comes into consideration such as:

1. Review expenditure to highlight suppliers who supply goods or services under contracts deemed to be high value or have a high risk exposure whether under individual contracts or aggregated under a number of contracts.

2. Seek advice from end users to verify the criticality of goods and services they have been provided.

3. Undertake assessments to define suppliers who may not have the annual expenditure required to categorise them as strategic suppliers, but provide critical goods and or services.

4. Confirm with Senior Management to confirm the inclusion of suppliers to strategic suppliers.

The attributes that influence such segmentation includes:

- Supply criticality

- Longer vs shorter term supply requirements

- Supply chain complexity

- Availability of alternative sources

- Supplier capacity

- Price, market competition

- Visibility of suppliers

- Suppliers willingness to engage

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

Supplier relationship management approach

As the value and risk of supply increases, some suppliers fall at the strategic segment and the corresponding relationship approach should be strategic.

Conversely, a low value, low risk supplier falls into routine segment and corresponding level of relationship is Operational.

The other two segments are called Focused and Leveraged and the corresponding relationship level is Tactical.

1. Operational management approach

This level of management is typically undertaken directly by the key recipient of the goods and or services within the business who has the responsibility to ensure that the goods and services are delivered based on the requirements of the contract and the specifications.

Standard contract management best practise should be applied, regular meetings, typically monthly should occur to ensure that complete visibility of the business requirements and the supplier requirement are being met.

In most instances, this level of management will be facilitated by the operational employee of the business and the supplier technicians.

2. Tactical management approach

This includes ensuring that key representatives from both the business organisation and the Supplier who have direct responsibility for the relationship are engaged and have an appropriate level of visibility of the arrangements.

Typically, Tactical Management will include meetings twice a year, or as agreed by both parties. The management will focus on ensuring that the key conditions of the agreement are being met and that opportunities to improve the relationship and minimise any challenges associated with the delivery of goods and services are understood and mitigated.

In most instances, this level of management will be facilitated by the procurement function of the business, key internal stakeholder and the supplier senior management.

3. Strategic management approach

This requires high level stakeholder engagement to ensure that the relationship at senior management level is in place and functioning in a positive manner. The focus of strategic management is to ensure that senior management from both the business and the strategic supplier have high level visibility of the relationship.

The challenges associated with the supply of the goods and services are dealt with high level priority. An understanding of the long term partnership exists that reflects appropriately on the nature of arrangements between the parties.

Contract management strategies for the suppliers

All suppliers need to be managed, but the key suppliers need to be managed differently. The level of communication and frequency between parties can be varied according to the relationship matrix.

For example, if a supplier belongs to the routine segment, the communication level should be operational, and the communication frequency can be low.

Conversely, if a supplier belongs to a strategic segment, the communication level will be at the strategic level, and the frequency should be high.

A similar distinction should be made in the contract management plan for other parameters, such as performance metrics, reporting requirements, etc.

Escalation process in strategic relationship management

In managing the strategic supplier relationship, there may be a requirement to formally escalate issues that may have an impact on the relationship. These issues may vary from minor operational to major strategic issues. Whenever an issue arises, the following should be taken into consideration:

- What is the nature of the issue?

- What is the impact to the business?

- What is the impact to the strategic supplier?

- Can the issue be addressed in a short time frame?

- Will the issue require a contract review/contract variation as a remedy?

- Is it a recurrent issue, has it occurred more than once?

250 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents are included each month. All written and updated by GMP experts. Check out sample previews. Access to exclusive content for an affordable fee.

If the issue meets one or more of the conditions, there could be a requirement to escalate the issue. In some instances, the escalation can impact the relationship with the strategic supplier. It is therefore highly significant to manage the process sensitive to the level of strategic supplier relationships.

Following are some tips to manage the escalation process that corresponds to each level of relationships.

a. Operational management

1. The issue should be clearly articulated in a formal mechanism; email will not suffice. The issue should be captured in the monthly meeting minutes with an action plan to address the issue, including a reasonable timeframe that is agreed by both parties.

2. The issue should then be monitored to ensure that the resolution is agreed and implemented prior to the due by date.

3. If the issue is not addressed to the satisfaction of business, the issue should be escalated to the representatives at the Tactical Management.

b. Tactical management

1. Tactical management representatives from both the business and the strategic supplier should review the issue and the historical events.

2. An action plan should be developed to address the issue to the satisfaction of both parties. The plan should be documented and agreed.

3. A time frame should be committed to and monitoring of the issue should occur by both the tactical and operational Managers to ensure that the issue is successfully addressed.

4. If the issue has not been resolved to the satisfaction of the business, advice should be supplied to the strategic supplier indicating that the issue will be formally raised with strategic management for resolution.

c. Strategic management

1. The operational and tactical managers should formally brief the business strategic management of the issue and the actions that have been undertaken to address the issue.

2. The business strategic management should then formally liaise with their counterparts at the strategic supplier to highlight the issue and the actions that have taken place.

3. Both parties should agree to an outcome and timeframes to ensure that the issue is remediated.

4. Ongoing management of the issue should occur by all three levels of managements (Operational, Tactical and Strategic).

5. If resolution of the issue has been achieved, the issue can be considered closed. If the issue is ongoing, formal legal advice should be sought in relation to legal avenues that can be taken to address the issue.

Challenges implementing supplier relationship management

It is important the business as the principal of agreement should have a clear policy, procedure, competency to deploy strategic supplier relationship management. In the absence of clear process and guideline a minor contractual and delivery issue can go out of control resulting in loss of trust, values and relationships between parties.

Sometime suppliers are not capable to operate within required economy of scale to support long term partnership. Financial viability of the supplier in the long run can also be challenging. Many strategic suppliers can go broke as the result of uncontrolled internal and external forces. In those cases, the business as the principal also become impacted through sudden supply shock.

It is also important for the business to play as a good customer role by releasing due payments on time and nurture the strategic long term partnerships, so both party can reap the success in their own terms.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.