Quality Management System in Good Manufacturing Practice

- Published on: Apr 11, 2021

The primary objective of a good quality management system is to ensure that the organisational processes consistently produce products or services which are safe, pure, effective, traceable and reproducible. This can only be achieved when a process performs robustly in a ‘state of control’ environment. All traceable auxiliary systems, which in combination build up the entire process, have to operate in compliance with defined specifications, in-house expectations (business rules), standards and regulatory frameworks.

The culture of good quality management system is not something happens by chance, nor it can be randomly chosen to make a process rocks of its own. The truth is everyone who takes part in that process must have defined responsibilities and participation in harmony to achieve the desired goal. This includes everyone from the senior Management to the stars of Operations.

Quality must be built into making a product or service which requires the right systems to be designed, integrated and implemented proactively at the infancy of the product or service lifecycle. Right through the beginning of the process. A retrospective control of quality testing is not very useful to guarantee reproducible outcomes as it does not detect the defects or deviations at the time of occurring.

In the paragraphs below, I would like to describe a few commonly practiced quality concepts which I have experienced in advanced level that contribute directly in quality performance. The outcome of which are quantifiable against set benchmarks.

Firstly, it is extremely important to define the objectives and measure the workflow activities (processes) required to culminate those objectives. This involves creating a quality policy as an overarching document that details the objectives, processes and breakdowns; Management responsibilities, review and notifications; training of people carrying out those tasks; validation concepts of methods and instruments; list of all support systems and sub-systems employed and their qualifications etc.

Secondly, standardisation must be achieved by creating standard operating procedures (SOP) and operating instructions (OI) for all operations. Document Control is used for timely review of procedural updates and track all changes from the inception. Controlled forms, logs, checklists and registers are used to generate records as evidence of work performed at Real-time. All documents must be controlled, no document should exceed the review period and a review must occur by due date at the minimum. Out of practice documents must be obsoleted and uncontrolled documents must be removed.

Systems should be in place to identify and investigate any unplanned departure from the standardised practices (ie. deviations, non-conformances etc). The investigation must aim to determine the root cause/s of the non-conformance. Appropriate corrective and preventive actions (CAPA) should be identified and implemented. The efficacy of the CAPA should be verified post implementations. Periodic trend analysis must be performed to ascertain any sign pf systemic failure in the process.

Any change of process must commence with a proposal first, risk assessed by SMEs & stakeholders and actions must be undertaken to mitigate the risks and impacts. All activities during the change should be documented using Change Management system. No change should be approved without prior risk mitigation. A change will only be closed successfully when all implicated systems will reflect the change.

Employee training is an integral part of quality system to ensure only trained and authorised personnel should perform a task. As such a well-designed training plan and matrix must be in place that correlates the employee job descriptions. New and refresher training should be provided for continuous development of personnel.

To ensure systems are in control and gaps are not remain hidden, periodic audits and self-inspections must be undertaken at risk-based frequencies. Any observed non-conformance and gaps must be agreed, reported and corrected to prevent further deviation.

In-process controls must be employed at critical control parameters. Inspections must be performed using validated methods and calibrated equipment. All tests have to comply specifications and any out of specification results must be investigated.

The quality of the suppliers and service providers have to be assessed and approved as per the risk profiles. Vendor assurance is as important as maintaining our own process quality. System should be established to encourage and report all customer feedback (complaints), investigate defects and apply corrective actions.

Finally, a comprehensive concurrent process review regime should be established so as to detect any deviation or failure within the process and be corrected in Real-time.

210 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

INTRODUCTION TO GOOD MANUFACTURING PRACTICE

GMP is a set of principles and procedures that, when followed, helps to ensure that veterinary products are consistently manufactured to a high quality, are safe and in accordance with their registration particulars and specifications when they reach the target species.

GMP principles and procedures for Pharmaceutical products are outlined in the local regulatory agencies Acts and Legislations typically in the name of “Code of Good Manufacturing Practice”. This code covers all aspects of manufacturing, including:

1. QUALITY MANAGEMENT

2. PERSONNEL AND TRAINING

3. PERSONAL HYGIENE

4. BUILDINGS, GROUNDS AND EQUIPMENT

5. DOCUMENTATION

6. PRODUCTION

7. INTERNAL AUDITS

8. COMPLAINTS AND PRODUCT RECALLS

Pharmaceuticals manufacturers must ensure to apply the GMP guidelines, practices, quality and regulatory requirements detailed in the GMP code into their products in order to maintain their license to manufacture and distribution.

QUALITY MANAGEMENT

Quality management is a core principle of GMP as it is essential that all veterinary products are fit for their intended use and do not place target species at risk due to inadequate safety, quality, efficacy, purity or identity.

Quality management within GMP covers:

QUALITY ASSURANCE

QUALITY CONTROL

PRODUCT QUALITY REVIEWS

QUALITY RISK MANAGEMENT

Licensed Pharmaceuticals manufacturer has workers, equipment and facilities to ensure quality of all products they manufacture. However, they also rely on their employees to participate in quality objectives. Therefore, it is everybody’s responsibility to identify and report quality issues to management immediately.

QUALITY ASSURANCE:

Quality assurance operates at the process level to ensure manufactured products meet quality standards. This means that we incorporate quality assurance systems and procedures when:

1. Purchasing and receiving starting materials

2. Producing products

3. Packaging products

The main aim of quality assurance is to identify and manage any quality issues before the product is completed and that the products we produce are fit for their intended use and they comply with registration requirements whilst ensuring that the target species are not at risk by inadequate quality, safety and efficacy.

QUALITY CONTROL:

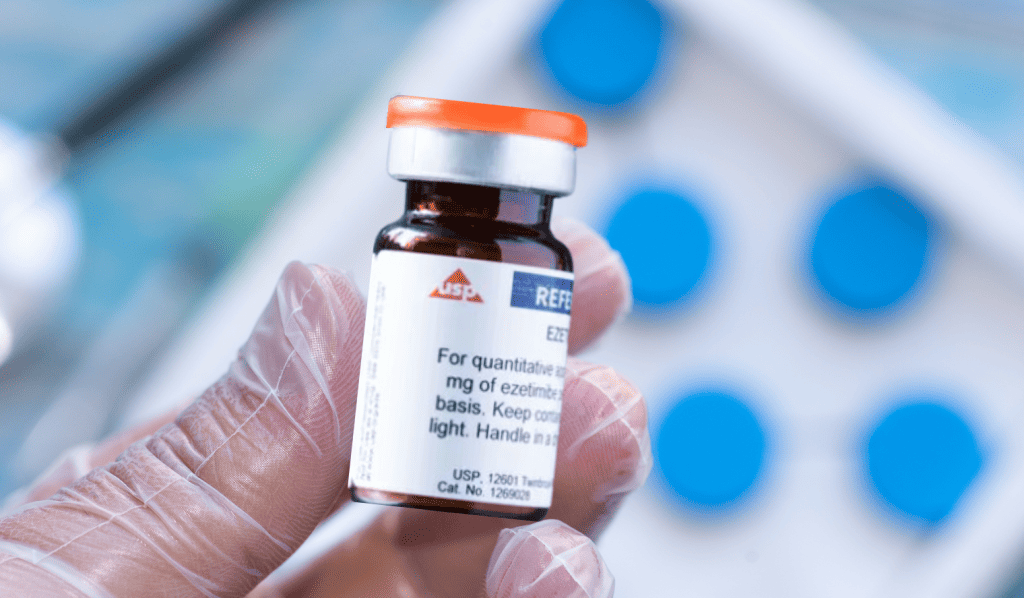

Quality control refers to the sampling, testing and results in order for products to be released for sale or supply. Finished products that do not meet quality standards must not be sold or supplied.

QC responsibilities include:

Sample receipt processes

Testing of samples of starting materials, process materials and finished products

1. Testing of media fills

2. Calculating and checking results

3. Recording all results

5. Water and environment sampling and testing

6. Animal and chemical testing

PRODUCT QUALITY REVIEWS:

Product quality reviews aim to highlight any trends and identify product and process improvements to determine whether changes or re-validation needs to take place. It involves verification of the:

Consistency of an existing process

Appropriateness of current specifications for both starting materials and finished products

1. Batch reviews

2. Testing reviews

3. Deviation reviews

4. Change controls

5. Recalls / returns

6. GMP agreements

7. Validation activities

8. Raw materials and packaging components used in the process

QUALITY RISK MANAGEMENT:

Quality risk management is a systematic process for the assessment, control, communication and review of risks to the quality of the veterinary product. It can be applied both proactively and retrospectively.

Overview of the QRM process:

1. Risk assessment – risk identification, risk analysis and risk evaluation

2. Risk Control – risk reduction, risk acceptance

3. Communication of outcomes to all stakeholders

4. Risk review – review events

Pharmaceuticals products cannot be sold or supplied before Quality Assurance have certified that each production batch has been produced and controlled in accordance with approved production and control regulations.

QUALITY OF PHARMACEUTICAL PRODUCTS

The four main components of quality when manufacturing pharmaceutical products are:

To ensure that the four components of quality are met in every aspect of the manufactured product, GMP principles, detailed manufacturing instructions and company procedures must be followed at all times.

Safety: The practical certainty that injury will not result from a substance when used in the quantity and in the manner proposed for its use. A reasonable certainty that the risk of harm to humans from the intended use of a substance is insignificant.

Efficacy: The ability of a pharmaceutical chemical product to perform according to label claims when used according to the label instructions.

Identity: This means having the correct product in the correct container, with the correct label.

Purity: Free from contaminants and pollutants and all foreign matter.

PERSONNEL AND TRAINING

The correct manufacture and quality assurance of pharmaceutical products relies upon people in the organisation. To meet the GMP requirements and ensure that everyone understands their position, role and responsibilities, the organisation has:

Organisational Charts:

The organisational charts illustrate the management and reporting structure, Quality Operations, Production and all support work areas. Staff should take some time to become familiar with these charts as they will help to understand who everyone should report any concern or incident once occurred within work area.

Written Job Descriptions:

All employees have written job descriptions which defines the position and duties of the role and limits of accountability and skills required to complete the role, particularly in regard to GMP. Job Descriptions should match tasks undertaken for that role.

Extensive Training:

Training is an essential requirement and it is very important that all employees possess the right level of skills and knowledge and have the right attitude to perform their work under GMP standards.

Employees must not complete any task that they have not been trained in nor documented that training. Staff must be trained and deemed competent by their trainer with documented training records before they can perform a task unsupervised.

To ensure that all employees understand their responsibilities, the organization should provide:

1. Induction training

2. Skills training

3. GMP / GLP training to new workers

4. SOP / OI training

5. Gowning qualifications and aseptic training

6. EHS training

7. External training related to roles

8. In-house and online training

Organization must demonstrate the completion of staff training by maintaining all training records for each member of staff.

PERSONAL HYGIENE

GMP requires all employees to maintain the highest levels of personal hygiene. This means that staff must:

1. Wear protective garments correctly

2. Wash your hands thoroughly

3. Wear clean latex gloves in laboratories, production and dispensing areas

4. Not smoke, drink or eat in production and storage areas

5. Leave personal belongings outside of manufacturing areas

6. Report any illnesses, infectious diseases or open lesions

7. Follow all other hygiene practices, as outlined in the organisation’s procedure

Wear protective garments correctly:

Organization should provide its employees with personal protective garments including coveralls, gloves, hairnets, beard / moustache covers, shoe covers and safety glasses.

These garments should be worn at all times in the production areas and be removed:

1. When leaving the production area (except during an emergency, where this is not necessary).

2. When garments become wet, dirty or soiled.

Coveralls must be discarded daily and sent for laundering.

Protective clothing from areas where live microorganisms are being cultured is to be decontaminated by autoclaving before being discarded or laundered.

Wash your hands thoroughly:

Hands should be thoroughly washed with soap on exiting laboratories, manufacturing areas, prior to eating, before commencing or returning to work and after:

1. Going to the toilet

2. Smoking

3. Handling food

4. Being contaminated with the product

5. Being contaminated with other contaminants

Organization should supply specific hand sanitiser stations at the entry and exit points of areas where controlled API materials are used and/or stored and must be used by personnel when entering and exiting these areas.

Wear clean latex gloves in laboratories, dispensing and production areas:

Clean latex gloves should be provided and must be worn in all product contact areas to protect both the employee and the product from contamination. You should also avoid touching exposed products and any parts of equipment that come into contact with products.

Gloves must be disposed of and/or changed when:

1. Leaving laboratories, dispensing and production areas

2. After completing one job and starting another

3. If the gloves come in contact with product

4. If the gloves become damaged, grotty or contaminated

Not smoke, drink or eat in production and storage areas:

Smoking is prohibited in any area, other than the authorised designated smoking area (outside the facility).

Food (including chewing gum and lollies) and beverages must not be transported through, stored or consumed in production and storage areas.

Leave personal belongings outside of manufacturing areas:

Employees must not bring personal items into laboratories, dispensing, production and storage areas. Such items can pose a risk of cross-contaminating products. The following are examples of these items:

1. Jackets / jumpers

2. Books / magazines

3. Handbags / wallets

4. Personal medication

5. Mobile phones / pagers

6. Some jewellery

Report any illnesses, infectious diseases or open lesions:

In order to maintain product quality, employees suffering from any of the following illnesses are not permitted to engage in activities where operator-borne contaminants may pose a risk to product quality. Such conditions must be reported to the area supervisor who will assign appropriate activities for the operator whilst so afflicted.

1. Coughs, cold or flu

2. Infectious diseases

3. Open lesions

4. Severe sunburn and peeling skin on an exposed surface of the body

Follow all other hygiene practices, as outlined:

All staff employed in manufacturing are required to comply with the following hygiene requirements:

1. minimising the use of jewellery and ensuring that it is securely contained under protective garments

2. wedding bands and earrings must be taped and covered

3. jewellery that may become detached or caught in machinery is prohibited in all manufacturing areas

4. make-up in all manufacturing and storage areas is prohibited

5. false nails and/or eyelashes in all manufacturing and storage areas are prohibited

6. operators must not have direct contact between their hands and exposed products or any part of equipment that comes in contact with product

7. every person (staff, visitors, maintenance, contractors) entering manufacturing areas must wear appropriate protective clothing)

8. protective clothing and factory uniforms are not to be worn outside the factory premises.

NOTE:

The wearing of wristwatches and jewellery (including earrings, studs and piercings is prohibited in aseptic processing areas.

The wearing of wristwatches and jewellery is probably permitted in packaging areas if covered by protective clothing.

BUILDINGS, GROUNDS AND EQUIPMENT

The layout of our premises and equipment has been designed to:

1. meet GMP Regulatory requirements

2. allow effective cleaning and maintenance to take place

3. avoid cross-contamination and the build up of dust or dirt and any other adverse effect on the quality of products.

4. protect against the entry of insects and other pests/rodents.

However, we rely on you to help us maintain the high standards of our premises and equipment to ensure that GMP requirements are met at all times.

Follow the steps below to ensure that the quality of premises and equipment are not adversely affected.

Step 1 – Conduct all work in such a manner that avoids causing contamination of materials or products.

Step 2 – Prevent the entry of any unauthorised person into the production, storage and quality control areas.

Step 3 – Perform cleaning activities of the premises and equipment in accordance with written procedures.

Step 4 – Store tools and parts in rooms or lockers reserved for that purpose.

Step 5 – Tag out defective equipment and remove it from the work area.

Step 6 – Do not use processing and packaging areas as thoroughfares and storage areas and keep doors closed when rooms are not in use.

DOCUMENTATION

Good documentation is another principle of GMP. Documentation provides essential information and procedures that when followed, helps to minimise mistakes and errors. Pharmaceuticals manufacturers have a range of documentation, including but not limited to:

1. Specifications

2. Master batch hand packaging instructions

3. Standard Operating Procedures (SOP), Operating Instructions (OI), Forms, Logs, Registers

4. Test methods, testing records

Employee should always perform their duties in accordance with the relevant documentation.

All master documents have unique document numbers and unique titles for identification and must be:

1. Signed at the bottom of the first page by the document writer

2. Authorised by department manager and QA manager

3. Controlled and distributed with care

Specifications:

Following are few types of specifications used by Pharmaceuticals manufacturer:

1. Packaging – labels, leaflets, cartons, shippers and inserts etc.

2. Components – bottles, caps, pillow packs, vials, applicators etc.

3. Raw materials and consumables – chemical and biological materials and cleaning reagents

4. Processing aids – filters, blue wrap, silicon tubing, clamps, kegs, carboys, bottles and aspirators

5. Finished products – all finished products manufactured on site and any product where a part of the manufacturing process is conducted by a third party

Master Batch and Packaging Instructions:

Master Batch records for each product and batch size manufactured, tested, packed and labelled:

1. Antigen production

2. Vaccine production

3. Pharmaceutical production

4. Secondary packaging products

SOP’s, OI’s, Logs and Forms:

Following are some examples of written procedures and associated records including but not limited to:

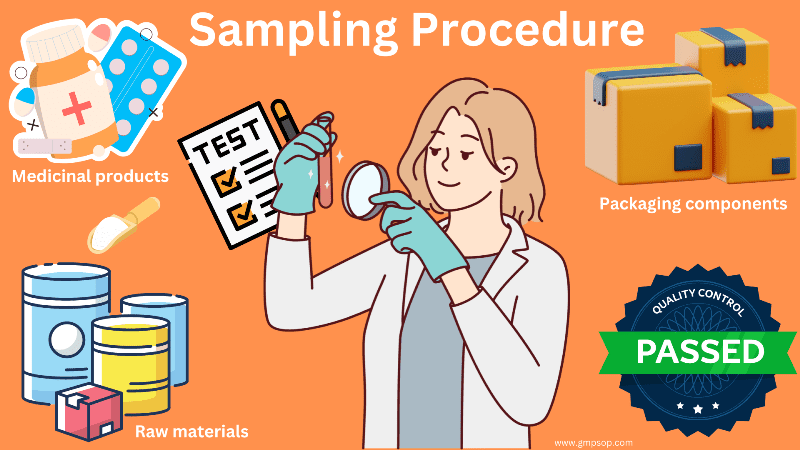

1. Receiving deliveries of materials

2. The labelling, quarantining and storage of materials

3. Sampling and testing of materials and products

4. Release and rejection

5. Batch processing and packaging

6. Validation

7. Equipment assembly and calibration practices

8. Maintenance, cleaning and sanitisation

9. Personnel matters including training, clothing, hygiene

11. Pest control

12. Complaints, recalls and returns

13. Supplier management

14. Internal audits

Test Methods and Test Records:

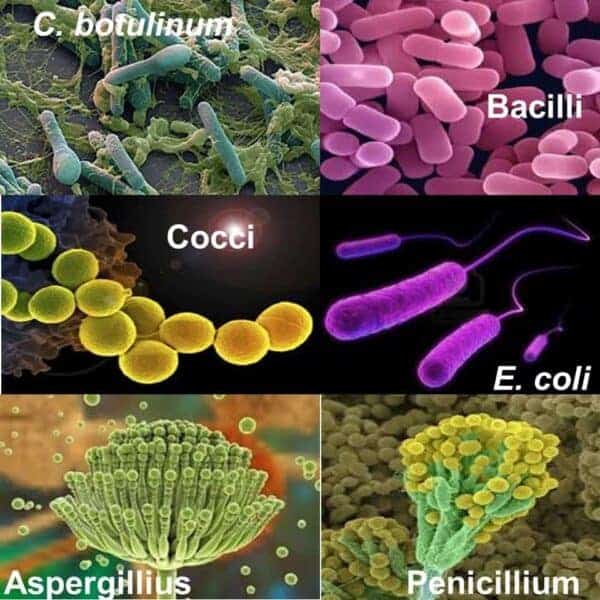

Test methods and test records describe the categories of products manufactured and the parameters and testing of each of the product categories. Inspection and reporting of results are described for each area of testing including but limited to:

1. Sterility

2. Microbiology

3. Immunology

4. Chemistry – pharmaceutical and biological

COMPLETING RECORDS

When completing an entry on a record or document, employees should always ensure that:

1. The form or document used is the current version

2. Complete the entry in real time – backdating entries or signatures is prohibited

3. The entry recorded is accurate

4. Handwriting is legible

5. Only use blue or black pen

The use of correction tape or liquid paper is prohibited. If an entry needs to be altered on a document, follow the process:

1. Draw a line through the error and initial and date the correction next to the corrected entry

2. Ensure that the correction allows the original information to be read

3. If the change is not obvious, record the reason for the alteration

4. Always cross out the full number/word or date rather than the individual digit/letter when making a correction

Important:

Signature and initial on a document are part of identity. This means that staffs are responsible for anything they have signed or initialled. If unsure about, or don’t understand the details of a document, staffs should speak to your manager before signing. Never sign or initial if you don’t understand!

PRODUCTION PROCEDURE

GMP outlines the requirements for every stage in the production process of pharmaceutical goods. Organisation’s procedural documents outline these processes. Employee must ensure that they handle materials at all stages of production, in accordance with these procedures. If any staff identify any damaged containers and/or other problems that might affect the quality of a material, they should immediately report the matter to your Supervisor / Manager.

1. Please ensure following good practices are followed all the time.

2. Production processes must be conducted in a way to minimise the risk of cross-contamination

3. Production processes must be validated to ensure that they are achieving the desired result

4. Starting materials must be purchased, received and dispensed in a manner that minimises risk

5. Processing operations must occur in clean, tidy and well-maintained work areas

6. Packaging materials must be purchased, handled and controlled in a manner that minimises the risk of contamination

7. Packaging operations must minimise the risk of cross-contamination, mix-ups and substitutions

8. Finished products must be stored and evaluated correctly before and during release

9. Rejected, recovered and returned materials must be managed according to their level of risk

INTERNAL AUDITS

Pharmaceutical manufacturers regularly conduct internal audits which is a way of verifying that all quality related activities comply with the code of GMP and with organisation’s standards. It also gives the opportunity to update any procedures and practices which may need to be improved.

There are 2 types of audits employ:

System audit: verifies that the systems work

Compliance audit: verifies that procedures and systems are in place

The local regulatory authorities also conduct audits of manufacturing sites and processes. During these audits, it is expected the organisation to continue your work as usual and, where required, answer any questions from auditors. Following the audits, organisations will take any required corrective action to rectify identified deficiencies or non-conformances.

COMPLAINTS

While the manufacturer make every effort to ensure their products meet GMP and the highest quality standards, there is a possibility that an individual will make a complaint about a product’s quality, or report a defective product.

Therefore, in accordance with GMP, the pharmaceuticals manufacturer should have procedures in place to deal with:

Customer Complaint:

Negative feedback from a customer regarding the product of a product or packaging, unrelated to administration to an animal or (inadvertent) administration to a human.

Customer complaints can also be described in a positive sense which can highlight a problem with a product or service.

Adverse Event:

An unintended or unexpected effect on animals, humans or the environment, including injury, sensitivity reactions or lack of efficacy associated with the clinical use of a veterinary or chemical product.

Organisation’s Complaints Procedure outlines the actions to be taken regarding complaints and adverse events, including:

1. Receipt

2. Response (including replacement samples managed by customer service)

3. Documentation

4. Evaluation

5. Management of complaint samples

6. Regulatory reporting

7. Investigation

8. Closure

9. All adverse events must be reported to the local regulatory authorities.

PRODUCT RECALLS

The Recall Procedure outlines the actions to take regarding recalls and applies to all products manufactured.

A recall may be necessary as a result of internal audit findings, investigations, customer complaints or because the quality or status of a product is determined to be questionable or unsatisfactory.

The level of a recall will depend on the adverse impact or potential adverse impact created by the use of the product. Local regulatory authority’s Recall guidelines must be used which are generally as follows:

Urgent:

Relates to recalls assessed as presenting a high risk (i.e. product defects / non-compliances that are serious or life threatening to the target species, consumers, operators or the environment).

Non-Urgent:

Relates to all recalls assessed as not presenting a high risk.

Note:

All recalled materials must be clearly marked and stored separately in restricted areas.

In summary, when the fundamentals of quality management system are adhered to ensure pharmaceutical products are safe, pure, effective and traceable for human and animal use a custom set of codes are derived which is known know as Good Manufacturing practice (GMP). They are in effect same in principles to produce best possible quality outcomes.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.

Related Posts

Biological Test Methods Validation in Pharmaceuticals

Stability programs overview for Pharmaceutical products

Good housekeeping practices in GMP

Yes

Thanks for your useful article. One other problem is that mesothelioma is generally the result of the inhalation of fibers from mesothelioma, which is a very toxic material. It is commonly observed among personnel in the building industry that have long experience of asbestos. It can be caused by moving into asbestos covered buildings for years of time, Family genes plays an important role, and some people are more vulnerable to the risk than others.