Quality Practices in Pharmaceutical Quality Control Laboratory

- Published on: Dec 16, 2020

Pharmaceutical quality control laboratory provides a vital function with regard to provision of accurate and reliable test results. Their customers rely upon these results to make important decisions particularly in the areas of patient health, consumer protection and the safety or suitability of materials, samples and products.

Therefore, it is important for all laboratory staff from Analysts to Supervisors to train themselves to:

- Recognize what comprises a laboratory quality manual.

- Relate the safety requirements of the QC laboratory to day-to-day work practices.

- Distinguish between the different types of laboratory documents.

- Stale the rules for record keeping and data recording.

- Recognize the key features of test methods and specifications.

Good Laboratory Practice (GLP)

Good laboratory practice generally refers to a system of management controls for pharmaceutical quality control laboratory and research organizations to ensure the consistency and reliability of results as outlined in the Organization for Economic Co-operation and Development (OECD) Principles of GLP and national regulations.

GLP applies to non-clinical studies conducted for the assessment of the safety of chemicals to man, animals and the environment.

Quality Systems in the Laboratory

It is well-documented that working within a documented quality systems framework will provide more consistency in laboratory processes, which will in turn improve the laboratory efficiency through error minimization.

Think of the consequential problems if, through a laboratory error, a medicinal batch is rejected when it is actually satisfactory. The company will lose the income that would have been generated from that batch. Even worse would be the situation where quality control laboratory incorrectly passed a defective batch this may have critical consequences for the company, through harm to patients, recall of the batch and loss of confidence in the company by the regulators and the public. Rather than simply being an overhead, the quality control (QC) laboratory is often the last chance to catch a problem before it becomes much bigger.

The QC laboratory must have quality system in place. The primary objective of the quality system is to assure the accuracy and precision of laboratory results so that they will be reliable, interpretable, repeatable and defensible.

A combination of GMP rules and ISO 17025 requirements provide a complete set of requirements for a regulated pharmaceutical quality control laboratory. However, in the pharmaceutical laboratories are audited and licensed according to the GMP rules themselves. ISO 17025 is more of an optional requirement.

ISO 17025 can be used by laboratories as a standard to develop and establish a quality system and for the assessment by their clients or by third parties. The standard is also being used as a criterion for laboratory accreditation but is not industry specific and compliance with this standard is not a regulatory imperative.

210 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

Role of the quality control laboratory

Quality control laboratory encompasses many compliance activities that are documented in the GMP rules.

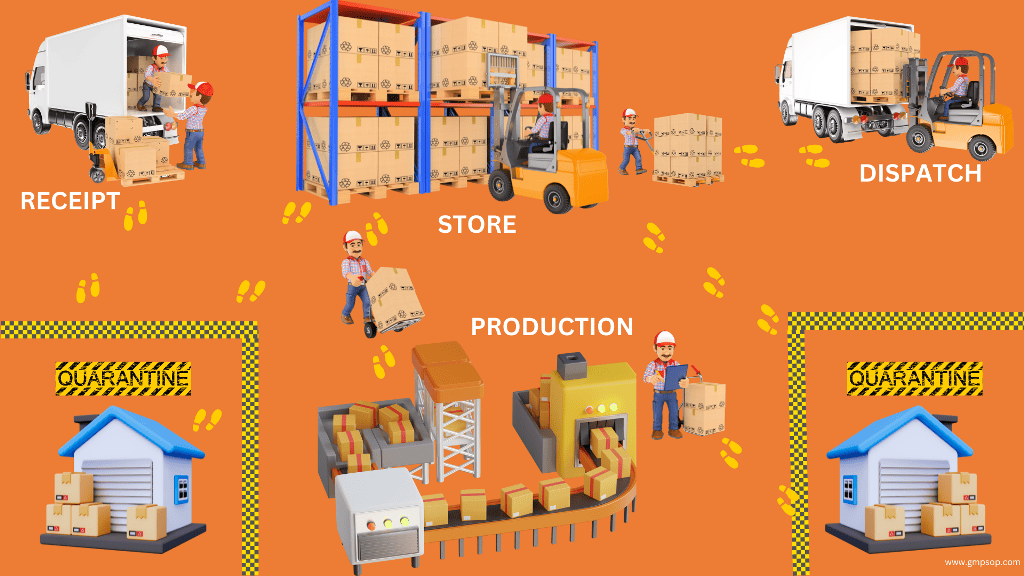

1. Sampling

Sampling of starting materials and finished products is completely governed by GMP regulations. All sampling procedures and plans must be documented.

If wrong or insufficient samples are taken or a poor sampling technique is used, any subsequent testing may then give misleading results. As a result, good product may be rejected, or much worse, defective product may be released.

2. Testing

Testing of samples in the laboratory is a mandatory requirement under GMP and GLP regulations. Its effectiveness, though, is limited because the entire batch cannot be tested nor can the batch be tested for all types of potential contamination.

In fact, quality control testing is limited to looking for defects after they have occurred, so it is not a quality assurance prevention system but rather a defect detection system.

3. Reporting results

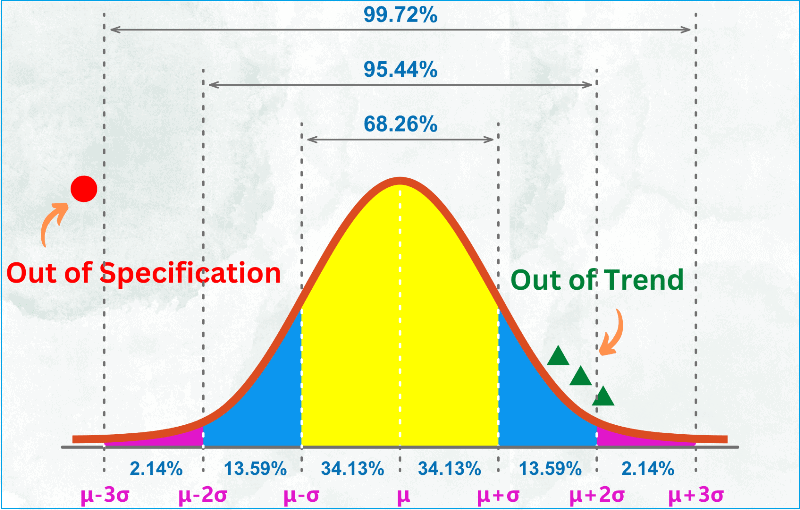

Each product has a specific set of specifications registered with the government authorities. Starting materials and finished products are required to be tested to these specifications and the results reported to QA management if there is a problem.

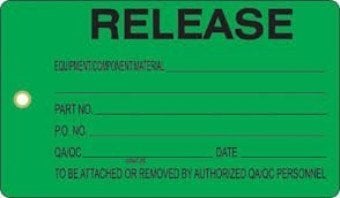

Batches may not be released to the market if results do not conform to the approved specifications.

4. Laboratory documentation

Laboratory documentation and records must follow the same rules as manufacturing GMP documents. The QC lab is required to have SOPs, test methods, specifications, registers, logs and testing records in place.

These documents must be current approved, accurate, provide traceability and be archived for later review. Government auditors are particularly interested in the QC testing records when they conduct GMP audits.

Documentation

Documentation provides personnel with essential information about relevant QA and GMP rules through SOPs, and excel ways to manufacture and test products safely through master instructions and test methods.

(Companies may have slightly different names for these documents.) Companies cannot have a quality plan without proper approved documents in place.

It is a GMP requirement that documentation must be followed exactly. Following documentation also helps minimize mistakes.

Training is an essential requirement under GMP: personnel must be trained before they are approved to perform o job. Untrained personnel will eventually make errors and mistakes that con cost lives.

It is a GMP rule that staffs are trained to the approved documents applicable to their work areas, and they must sign to the effect that they understand the requirements.

Audit

Self inspections or internal audits, are requirements under GMP. The purpose of a self inspection is to independent check that the rules and documents established by QA management are being followed. Self inspections also provide opportunities to improve procedures and practices in the factory.

Corrective action

Corrective action is required when an internal audit reveals a problem that might affect the quality of a product.

Corrective action may also be required when a problem occurs in production.

Corrective actions must be documented, and incorrect procedures updated, in order to improve the company’s quality plan.

Laboratory Quality Manual

Generally, the quality manual references or lists the SOPs that are used to run the laboratory.

The manual is used to:

- Induct new staff into the tab

- Provide a reference document for stall and interested third parties

- Describe the range of lab controls and checks

- Describe reporting responsibilities

Contents of a laboratory quality manual

The quality manual should specifically describe or refer to:

- The Laboratory Quality Policy, commitment and objectives

- The standard of service and governing standards (e.g. ISO 17025, GMP)

- Laboratory SOPs and technical methods

- How independence of judgment is demonstrated

- The responsibilities and authority for key personnel

- Qualifications and job descriptions (organizational structure)

- The management elements of ISO 17025

- Deployment of the procedures and standards and training for personnel

- QA programs (audit, review & improvement)

- Document control records management and archiving systems

Laboratory Quality Policy

The following are some Items that should be covered in the Laboratory Quality Policy:

- Conflict of Interest, ethics and referenced standards

- Maintained and deployed procedures for laboratory operations, and tests based upon referenced methods for testing.

- Sample handling to maintain integrity of the analytical data

- Maintenance of records to facilitate retrieval

- Employment of qualified and trained personnel

- Routine maintenance of laboratory data to support test results

- Maintenance of an instrument calibration program that provides measurement traceability to International System of Units (SI units)

- Change control for management systems and test methods

Laboratory Document Change Management

The laboratory relies on multiple documents to ensure that the right tests are conducted, only current test methods are used, and the results ore compared against the current and approved specifications.

The laboratory WPs, tests, methods, and specifications are under version control. In order to update any one of these documents, a change request should be raised and approved by management.

A written process is also needed for changing the internal document to match the latest industry standards or official regulatory documents and/or pharmacopoeias.

Important laboratory SOPs

The laboratory manual and written procedures should reflect the requirements of ISO 17025. Even if a laboratory does not intend to be certified to this standard, there are some essential procedures that are needed, these include:

- Laboratory management and organization

- Records, documentation and archiving

- Reagent and standard quality control

- Test method validation and control

- Instrument calibration and maintenance programs

- Material and product specifications

- Quality, integrity and authenticity of data

- Sampling procedures

- Personnel training

- Trend analysis, audits and reviews

QC staff should be familiar with the following key SOPs.

- Management structure, responsibility and authority

- Apparatus and instrument use and maintenance procedures [per instrument)

- Record keeping, reporting, storage, archiving retrieval systems

- Completion of laboratory records, workbooks, logs, and registers

- Handling out-of-specification (OOS) conditions

- Release of results from the laboratory

- Sample receipt identification, labeling, handling, traceability and protection

- Analytical method validation and change/updates

- Computer security restrictions and data entry

- Reference standards control

- Laboratory calibration and performance check program

- Retention samples control

- Training programs

Training of personnel

Under ISO 17025, a key element for personnel is appropriate training and documentation of all training activities. For example, operators of a chromatographic system need to get trained before they operate the instrument, and internal auditors will have to be trained prior to conducting internal audits.

The ISO 17025 chapter on personnel covers:

- Competence through appropriate education, training, experience and/or demonstrated skills. This may include relevant knowledge of the technology and legislation/standards and to understand significance of deviations.

- A laboratory policy to identify training needs and goals or objectives for education, training and skills.

- That the laboratory ensures its people are supervised and competent

- Development and maintenance of job descriptions with responsibilities

- The laboratory shall authorize people for specific tasks

Knowledge of QC principles

An effective training system requires that staff have a working knowledge of the principles of running a QC laboratory. This also includes the understanding of GMP as its applied to the laboratory (This forms the knowledge base for more technical training.

Understanding of SOPs

All laboratory staff, including managers, supervisors, and analysis, should understand the intention and content of the SOPs that apply to them. They should be able to follow the SOPs and interpret them accurately.

Interpretation of test methods

A fundamental requirement for laboratory analysis is to be able to accurately and repeatedly understand and interpret the requirements within specific test methods. Test methods should be written unambiguously, and analysts should be trained in the application of each specific test method.

Application of analytical techniques

The competency of analysts to execute test methods using appropriate analytical techniques is on essential success factor for running a QC laboratory. Analysis must be able to operate complex instrumentation, prepare samples, and interpret the data. And calculate the results without error. The application requires competency assessment.

Basic Quality Control Safety Practices

Laboratory personnel sample and test all chemicals that pass through the factory, and as such may be exposed to potential hazards.

It’s vital that all chemicals, and particularly potent materials, are handled according to the MSDS and sampled according to the specific sampling procedures for that material. This often means wearing masks, gloves, and in some cases respirators, as well as sampling in a biological hazards safety cabinet.

An essential part of induction for new laboratory employees is familiarization with laboratory safety rules and requirements: in particular, the handling of corrosive substances, the wearing of protective garments, eye protection, and familiarity with the MSDS.

Many laboratories include particular safely requirements relating to an instrument or a test method within the test method document itself. Before commencing any test, the analyst should be familiar with these safely requirements.

There are quite a few hazards in a laboratory, including, but certainly not limited to, the following:

- Unprotected use of solvents

- Equipment not being stored correctly

- Chemical exposure or spillage

- Broken or exploding gloss

- Untidy physical environment

- Repetitive strain injuries

Types of Dangerous Chemicals

Classes of dangerous chemicals include:

- Explosives and gases

- Active materials, e.g. cytotoxics

- Flammable materials

- Peroxides and oxidizing agents

- Poisons and infectious substances

- Radioactive materials

- Corrosives

What is a Material Solely Data Sheet (MSDS)?

A MSDS provided by the supplier is designed to provide both workers and emergency personnel with the proper procedures for handling or working with a particular substance or when on accident occurs.

The MSDS includes information such as:

- Physical data on safe handling

- Toxicity limits

- Health effects on exposure

- First aid on exposure

- Reactivity with other chemicals

- Safe storage

- Sole disposal

- Use of personnel protective equipment

- Recommended spillage and leakage procedures

Basic Laboratory Safety Rules

Here are some basic safety rules for working in a QC laboratory:

- If in doubt don’t proceed! Ask a supervisor.

- Always read any caution statements before commencing any procedure or test method.

- Read warning labels and check the MSDS for information on handling.

- Always use and wear protective equipment when handling chemicals.

- Always check the laboratory manual. SOPs and test methods for safe handling details.

- Never handle chemicals by hand.

- Do not pipette any chemicals by mouth.

- Immediately clean up spillages.

“A place for everything, and everything in its place.”

The laboratory is generally a safe place to work, but most laboratories are busy, have complicated instruments, and handle corrosive or poisonous chemicals.

One of the basic rules in any workplace is to practice good housekeeping. While this is a fundamental requirement for manufacturing GMP, it is also applicable to the laboratory, not only for safety reasons, but also for efficiency reasons. Good housekeeping practices means that everything has a designated place and when instruments and chemicals are not in use they should be returned to their designated location.

Critical aspects of a safe and efficient workplace include:

- Regular and proper housekeeping

- Storing dangerous reagents and chemicals in designated places

- Observing rules for safe-handling

Important housekeeping rules

These are some of the more important housekeeping rules applicable to a laboratory:

- The golden rule in any laboratory is if you’re unsure about any technique or practice, do not proceed. Ask for advice from supervision.

- Never handle chemicals or instruments if you don’t understand the safety implications.

- At the end of each day, clean down workbenches, reseal solvents and reagents, and dispose of surplus materials.

- Clear out all expired reagents and standards regularly.

- Certain solvents and acids must be stored in corrosive-proof safety cabinets, and must be transported in safety containers.

- Ensure dress is according to lab dress codes. This includes gowns, footwear, eye protection, and gloves when handling corrosive chemicals.

- Complete records and documents in real time, and file them away from the workbench.

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.

Related Posts

What is quality risk management in pharmaceutical?

04 Steps to Investigate Out of Specification (OOS) Result

Equipment Cleaning Practices for Drug Products Manufacturing