Supplier Assessment Procedure for GMP Facility

- Published on: Dec 16, 2020

Purpose

The purpose of this procedure is to create guidance on new supplier assessment, approving new suppliers and the maintenance of approved and inactive suppliers for GMP facility.

Scope

This procedure applies to suppliers that provide the following:

Medical devices (including testing and calibration) and drug products Contractors and contract services related to the services provided for medical devices and drug products. Services that may affect the quality or integrity of medical devices and drug products i.e. warehouse cleaning, temperature monitoring etc.

This procedure does not apply to suppliers that provide material and/or services used for building maintenance, repairs and operational supplies that do not affect the quality or integrity of medical devices or drug products.

Responsibilities

It is the responsibility of the Regulatory Affairs Department to implement and maintain these procedures.

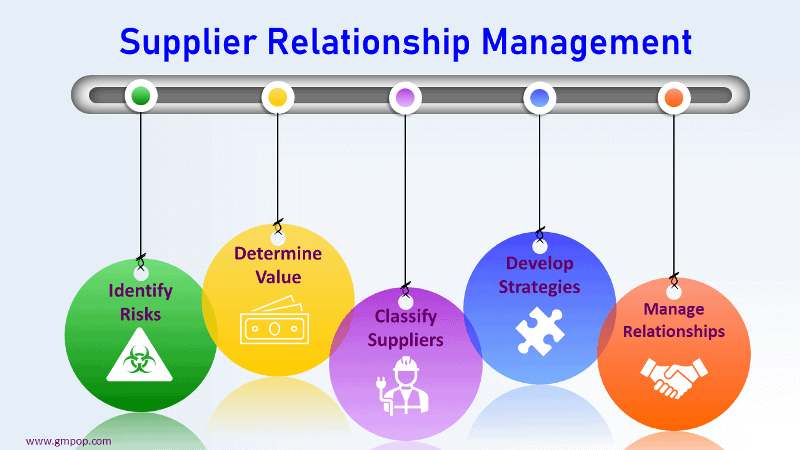

The Regulatory Affairs Department shall have the responsibility for the final supplier assessment and approval of supplier. Regulatory is also responsible for supplier relationship management.

Regulatory will maintain the Approved and Inactive Supplier Lists and ensure that no medical device, drug product, or Services are purchased from a supplier prior to that supplier receiving approval.

It is the responsibility of Operations or Executive Assistant to enter a Purchase Order (PO) on the system, after ensuring the supplier is on the approved list.

When products or supplies are received, the warehouse and /or service staff shall verify that they are received from an approved supplier. The warehouse and/or service staff shall notify Regulatory when the products or supplies are received from an inactive supplier or a supplier not listed on the approved supplier list. The item will be placed on “QA Hold”, pending a decision on the supplier’s approval.

210 SOPs, 197 GMP Manuals, 64 Templates, 30 Training modules, 167 Forms. Additional documents included each month. All written and updated by GMP experts. Checkout sample previews. Access to exclusive content for an affordable fee.

Supplier Assessment Procedure

1. Selection of the Supplier

The first step to supplier assessment is to identify potential suppliers by the GMP facility based on the needs of the company who will possibly satisfy the necessary product attributes or service requirements. They can be identified in a number of ways:

– Existing suppliers with proven ability to meet the criteria.

– Recommendations from other affiliated groups or other suppliers whose products or services are acceptable to the service provided.

– As part of supplier assessment each potential supplier shall be sent a Supplier Evaluation Checklist and requested to complete the document, returning it at the earliest possibility to the Regulatory Department for approval.

– Completed questionnaires will be held in the Regulatory Department.

– If a supplier is evaluated through Global Supply Chain, records held by the Global Supply Chain may be used during supplier assessment and a Supplier Evaluation Checklist may not be required.

– If the supplier does not return the Supplier Evaluation Checklist a follow up shall be initiated, by phone, fax or e-mail by the Regulatory Department. Alternate Suppliers (where available) may be contacted if no response is received.

– The returned Supplier Evaluation Checklist shall be reviewed by Regulatory to assess the suitability and /or criticality of the supplier. The suitability and criticality shall be related to the products and services provided.

– If the Supplier does not meet the scope of this procedure, this supplier does not require approval.

– Suppliers used prior to the implementation of the first issue of this procedure shall be grandfathered and will not be required to go through the initial supplier approval process.

2. Approval of the Supplier

The approval for a supplier shall be made by Regulatory who will also maintain the supplier lists. The process of evaluating, selecting and controlling can include (where applicable):

3. Review of third-party evaluating reports

Review of historical data, such as records of past performance kept on accounting files Certification by a third-party of the supplier’s quality management system.

Auditing of the supplier’s quality management system by the organization.

After Regulatory approval the appropriate lists shall be updated by Regulatory to include new suppliers and a file shall be created by Operations or Regulatory for each supplier. If Regulatory does not approve the supplier, the supplier will not be recorded on the Unapproved Supplier List and the unapproved checklist shall be filed.

If an approved supplier is no longer used, the supplier shall be removed from the Approved Suppliers List and added to the Inactive Supplier’s List.

4. Ongoing Assessment of Approved Suppliers

Routine performance review should be conducted regularly by the Regulatory Department.

All critical suppliers shall be reviewed annually. A new supplier evaluation checklist shall be sent as a part of the routine review.

All non-critical suppliers do not require an annual review and shall be reviewed as needed.

If the supplier does not return the Supplier Evaluation Checklist, a follow up shall be initiated, by phone, fax or e-mail by the Regulatory Department.

A review of the suppliers shall be reported by Regulatory or the Director of Commercial Operations during monthly and annual review QMS meetings. Any issues raised shall be followed up and clarified.

If conditions of the supplier have changed, Regulatory shall be notified and shall make the necessary decision whether to approve the supplier.

5. Supplier Audits

The Regulatory Affairs / Compliance Team along with Supply Chain may choose to audit a supplier at any time.

All supplier audits must be performed in accordance with the External Audit procedure.

Records will be retained in accordance with the Document Retention Matrix

Author: Kazi Hasan

Kazi is a seasoned pharmaceutical industry professional with over 20 years of experience specializing in production operations, quality management, and process validation.

Kazi has worked with several global pharmaceutical companies to streamline production processes, ensure product quality, and validate operations complying with international regulatory standards and best practices.

Kazi holds several pharmaceutical industry certifications including post-graduate degrees in Engineering Management and Business Administration.

Related Posts

Guideline for the validation of Excel spreadsheets

Deviation Investigation Guidelines in GMP Facilities

Cleaning Validation for Active Pharmaceutical Ingredients